Coating Services

IPS applies a coating composition formulated for protecting ferrous alloys from both high temperature heat oxidation and at the same time offer sacrificial (cathodic) protection to the base metal. Because of its high temperature capabilities, it offers excellent protection when exposed to cyclic high temperature and corrosive salt environments, continuing to provide sacrificial properties at temperatures to 1150°F. Although a ceramic coating, it combines thermal stability, excellent adhesion and hardness, along with good flexibility... a property not found in most ceramic coatings. As mentioned above it offers salt corrosive protection to 1150°F. At about 1200°F. the aluminum oxidizes to a point where it no longer provides its excellent sacrificial properties, however, it will continue to offer excellent heat oxidation continuously to 1600°F. and in some cases, depending on metal substrate, has offered heat oxidation protection to 2200°F. Tests have been conducted using low carbon steel alloys. There was no loss of weight after several weeks continuous exposure at 1000°F. After exposure to 5% salt spray for 1000 hours, there was no evidence of corrosion. Further, the coating formed composition offers superb thermal shock resistance. The coated metal will not crack, spall, or fail after shocking from 1100°F. to room temperature repeatedly.

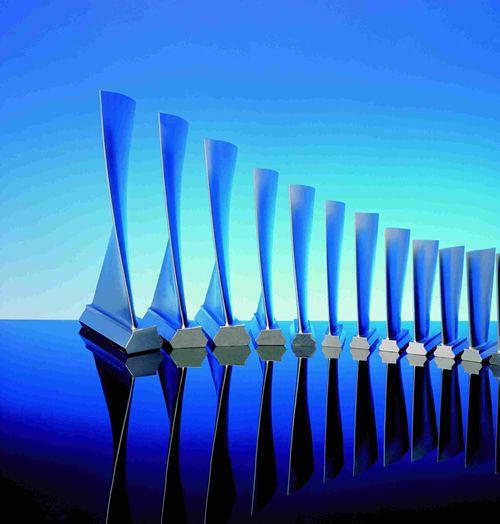

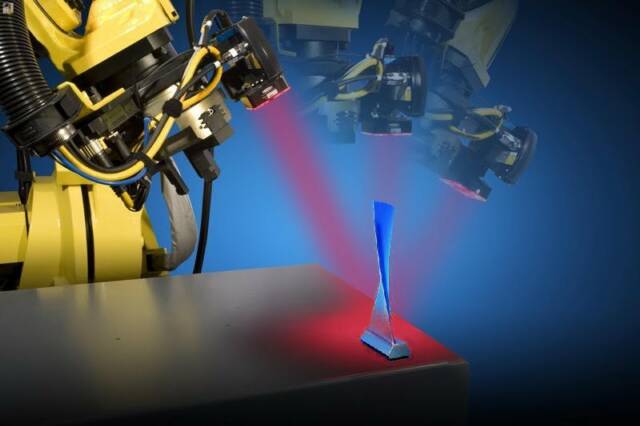

Robotic Coating Application and Shot Peening Services

Innovative Peening Systems

2825 Simpson Circle, Norcross, GA 30071

Phone 770-246-9883, Fax 770-246-9860

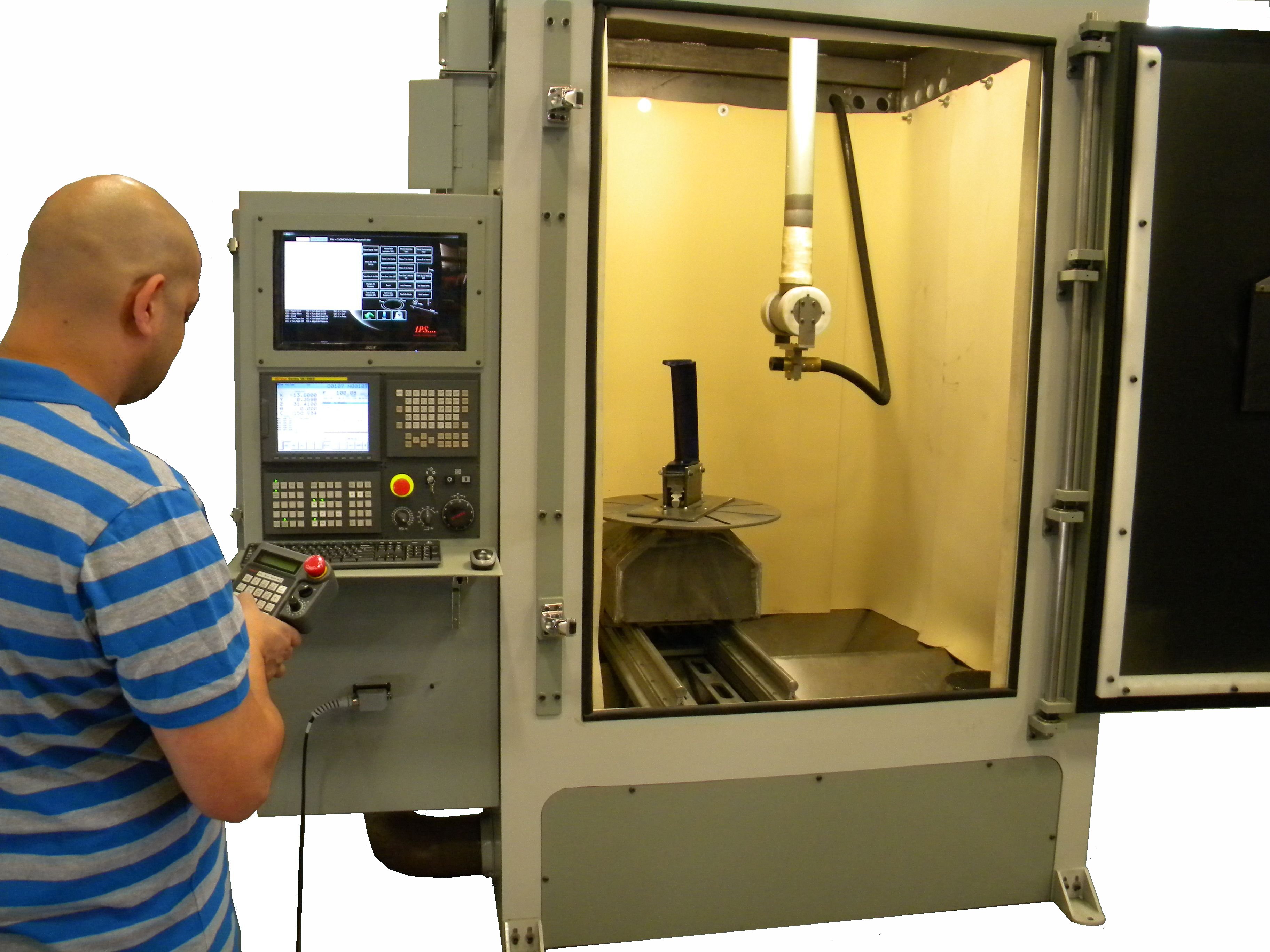

Machine Rebuilding and Repair.

IPS offers total shot peening and blasting machine repair and modifications. We can provide major component replacement that comply to current certifications. Our experienced team of machine builders provide both mechanical and electrical rebuilds either in the field or for larger projects, in our facility.

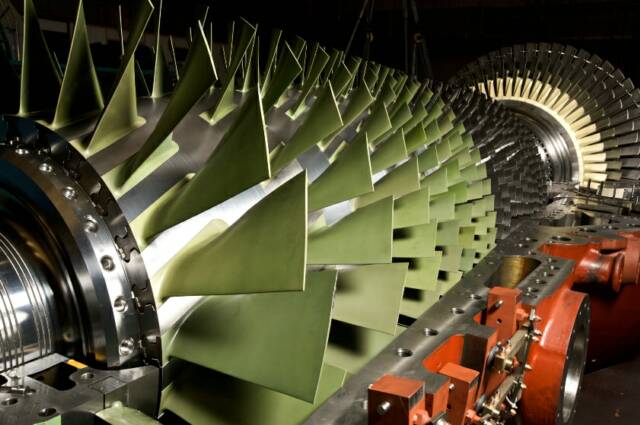

Shot Peening and Abrasive Blasting

IPS offers contract shot peening and abrasive blasting services. Shot peening a cold working process that induces a compressive stress layer into the surface of metal part greatly increases the fatigue life of parts. Abrasive blasting removes coatings and applies an angular surface layer to parts for the purpose of cleaning the surface then allowing the profile to anchoring applied coatings to the parts.

Job Shop Services

IPS....

Innovative Peening Systems